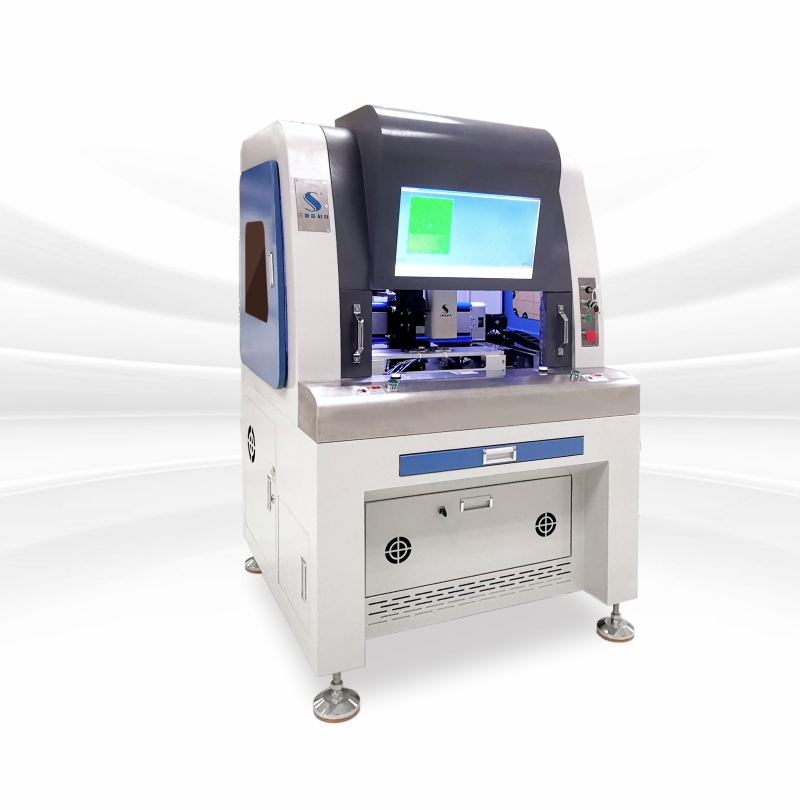

Standard Equipment

Testing equipment for metal and plastic structural parts of smart watches

- CCD vision inspection, laser measurement, confocal spectroscopy

- Dimensional dimensions, height dimensions, contouring, gaps, segmental differences, cosmetic defects, etc.

- Suitable for metal or plastic structural parts of smart watches, etc.

- Inspection accuracy up to ±0.005mm

- Inspection speed up to 1600PCS/H

Project Requirement

Performance Indicators

Detection Advantage

Equipment Capability

Video Presentation

With the continuous development of mobiles technology, smart wearable devices have gradually become popular in people's lives, for the inspection of smart wearable products Samson has introduced a set of relatively complete inspection solutions, which can meet the height of metal or plastic structural parts of smart watches such as size, contour, gap segment difference, appearance defects and a variety of testing needs.

| Model | SC-190 Series | |

| Equipment name | Smartwatch structural component inspection equipment | |

| Testing products | Metal and plastic structural parts for smart watches | |

| Detection function | External dimensions, height dimensions, contours, gaps, segment differences, cosmetic defects, etc. | |

| Software | Samsun SMV vision inspection software, Samsun SML laser measurement software, Samsun SC spectral confocal inspection software | |

| Detection accuracy | ±0.005mm | |

| Testing features |

Fast measurement speed: 3~8S/PCS

Process improvement: assist in improving product yield by more than 1%

High measurement accuracy: Repeat accuracy ±0.005mm, leading in the same industry measurement, with strong versatility.

Easy to operate: automatically complete measurement and save data when placed into the product.

Convenient management: export statistical reports can be generated according to customer requirements, facilitating customer management and improving product quality.

|

|

| Production capacity | 1600PCS/H | |

| Main configuration measurement methods |

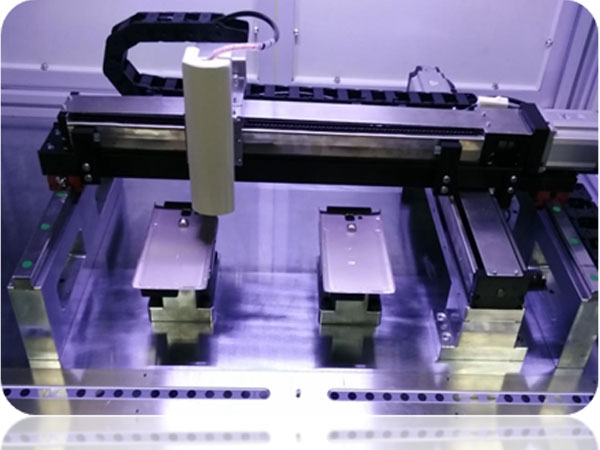

Industrial image processor: dual-core CPU, 4G memory, 1T hard disk, 21" LCD monitor

2~5 five million industrial cameras, 1~2 line laser

Samson vision inspection software SMV, Samson laser inspection software SLM (online real-time data collection, tolerance free setting, automatic judgment OK/NG) High precision motion modules, motion servo, motors, etc.

|

|

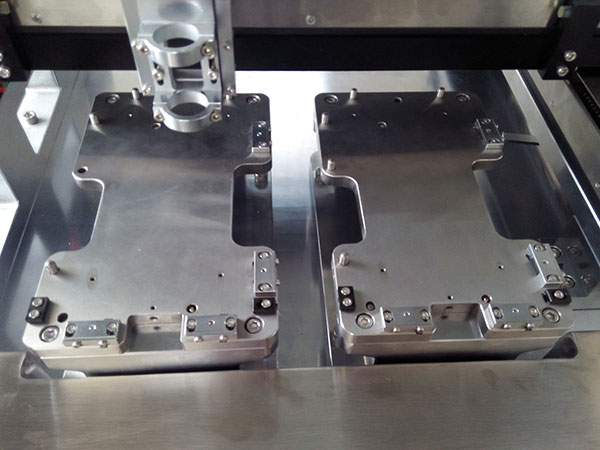

| Loading and unloading method | Manual loading and unloading | |

| Detection method | CCD vision inspection, laser measurement | |

| Inspection stations | 2~5 CCD, 1~2 laser | |

| Dimensions (L*W*H)mm | 2000*1300*1780 | |

| Weight (kg) | 1000kg | |

| Working environment | Temperature: 20°±2° (no dew point) Humidity: 30~80% | |

| Air pressure, voltage | 0.5Mpa-0.8Mpa/220V | |